Sysrev Helps Create Chemical Transparency for Manufacturers

SysRev allowed us to remotely extract chemical information from SDSs at three separate facility locations using multiple people. The process was easy, verifiable, inexpensive...

"The process was easy, verifiable, inexpensive and helped us achieve our chemical management goals and obtain LEVEL® sustainability certification for our products.”

The “radical transparency” movement is impacting how customers assess purchasing decisions of manufactured products. For many companies, this trend has caught them unprepared to respond to customer inquiries concerning potential chemicals of concern (CoC) as their customers are demanding to know more about the chemical ingredients used in transforming raw materials into their final products.

The diversity and use of chemicals, especially in consumer products and building materials, continues to grow. According to the American Chemistry Council, chemicals are now used in 96% of manufactured materials and products. It is estimated that there are currently over 80,000 chemicals on the market, with an average of 2,000 more being introduced each year.

SRG is assisting its manufacturing clients to build a strong foundation to incorporate CoC transparency into their product offerings. The solution being devised by SRG is a combination of existing sound management practices combined with innovative software technology. Good chemical management practices are the basis of a well-developed CoC strategy. This requires a chemical management plan that covers purchasing decisions, inventory control, health and safety training, oversight of chemical use and the final disposition of managed chemicals.

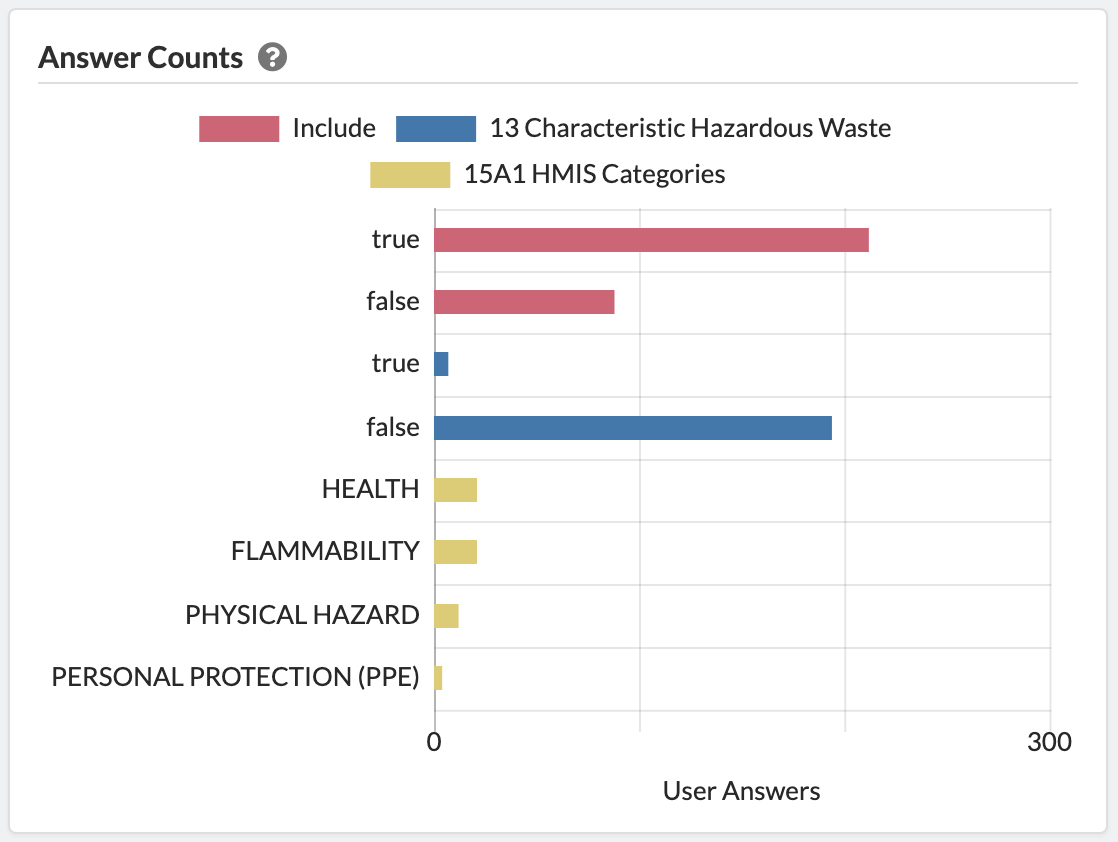

The most accessible point for beginning to develop a plan is collecting current Safety Data Sheets (SDSs) for each chemical used in the product, the process and during maintenance operations. SRG enters all relevant chemical data into its Excel-based Chemical Management Tool and the tool then sorts the chemicals to highlight any that are identified within a dataset as a chemical of concern. The datasets of CoCs may be different for each company and could include EPA’s SARA Title III chemicals, California Proposition 65 Chemicals, the European Union’s REACH chemicals, or the Living Building Challenges “Red List” of chemicals. These lists help manufacturers identify chemicals within their processes or products that may pose serious risk to both human and environmental health.

Over time as a company’s CoC chemical datasets becomes more complete the company will be able to quickly and efficiently track or search an individual chemical, or groups of chemicals to obtain answers for the company and its customers. SRG is now partnering with a new software developer called Sysrev to help automate the data entry process of Safety Data Sheet (SDS) information. The partnership will help reduce data entry time, human error, and provide additional cross-referencing capabilities to other chemical databases. In its first year of using Sysrev, SRG assisted in modifying the software’s approach to help its clients enter chemical and safety information from thousands of SDSs.

According to Ed Taylor, Vice President of Environamics, Inc. “Using SRG’s version of Sysrev allowed us to remotely extract chemical information from SDSs at three separate facility locations using multiple people. The process was easy, verifiable, inexpensive and helped us achieve our chemical management goals and obtain LEVEL® sustainability certification for our products.”

In the future, the development team is working to automate the data entry process using “machine learning” to include other inputs such as invoices, labels, and technical sheets beyond SDSs and to speed up the overall data entry and assessment process even more. The end-result is a rapid response to complex chemical transparency inquiries.